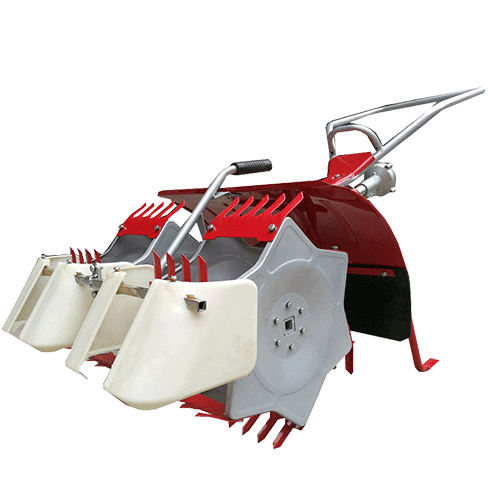

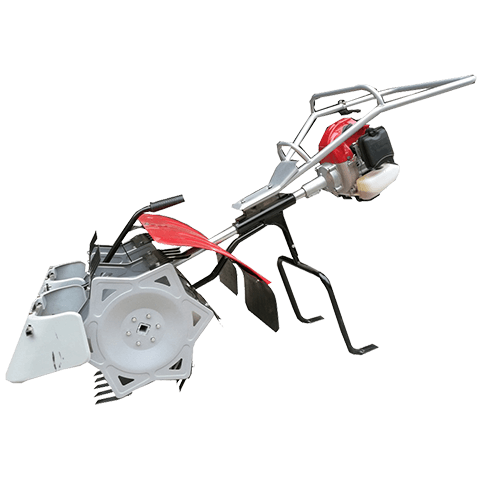

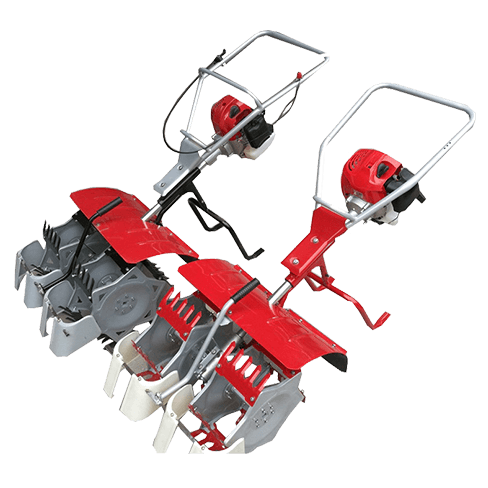

2 Rows Weeding Machine

This paddy weeder applied to weed in rice field. It can replace the herbicide to reduce the environment pollution and avoid soil compaction. This paddy weeder has been a necessary tool for rice planting. The size is small size and the weight is light. It is easy to move and economical and practical.

|

Items |

Technical parameter |

|

|

Model |

WFW-2 |

|

|

Engine |

Type |

Petrol engine |

|

Rated power |

1.46 KW |

|

|

Rated speed |

6500 r/min |

|

|

Machine Overall Dimension(L*W*H) |

L1350×W540×H890 mm |

|

|

Cultivating depth |

10~20 mm |

|

|

Working rows |

2 |

|

|

Weeding Width |

170mm×2 |

|

|

Number of weeding rake |

6(Effective length 56 mm; depth 20 to 50mm)×2 |

|

|

Blade axle speed |

186 r/min |

|

|

Transmission mode |

Middle shaft drive |

|

|

Connection mode |

||

|

Speed |

2.79~4.30 hm/h |

|

|

Efficiency |

0.13~0.20 hm2/h |

|

|

Weight |

24 Kg |

|

|

|

||

|

Package |

Plywood box packing |

|

|

Wooden box size |

L860×W460×H460 mm |

|

|

Gross weight |

35 kg |

|

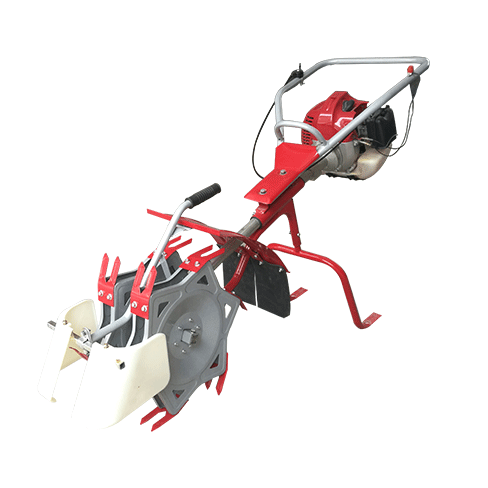

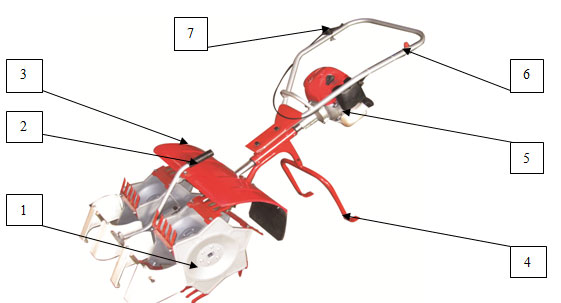

1. Working parts

1. Working parts

2. Handle

3. Mudguard

4. Cradle

5. Engine

6. Switch

7. Throttle switch and throttle wire

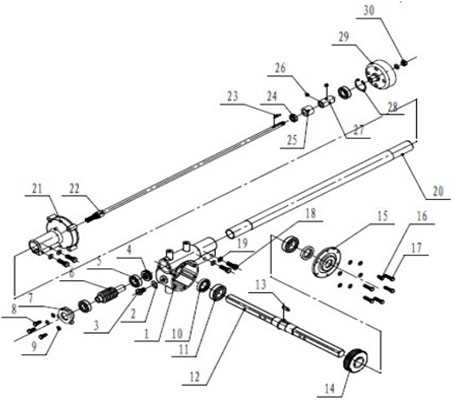

1. box 2. sealing ring 3. bolt M10×16

1. box 2. sealing ring 3. bolt M10×16

4. thrust ball bearing 5.deep groove ball bearing

6. worm 7. end cover 8. bolt M6×16 9. washer φ6

10. sealing ring 25×40×7 11. deep groove ball bearing

12. turbine shaft 13. flat key 6×22 14. turbine 15.cover 16. bolt M6×12 17. bolt M6×25

18. bolt M8×25 19. washer φ8 20. external casing 21. clutch sleeve

22. spline driving shaft parts 23. flat key 3×24 24.deep groove ball bearing 25. shock absorption set 26.tightening screw 27. limit set 28. hole fileφ35 29. clutch friction ring 30.screw M8

Whether the performance of paddy weeder is on the good condition will directly affect the work efficiency. The method of using and maintenance as follows.

1.Before using the paddy weeder, you must idle running a few minutes and check the lubricating oil. Clean up the sundries during work in order to avoid working parts damaging. The continuous working time should not be too long. Work one hour, rest 15mintues. After use, shut off the engine power, clean the machine completely, and then check the blade and vulnerable parts whether damage or loose. If necessary, maintain or replace it.

2.Maintenance by professional servicemen before first use every year.

3.The paddy weeder should be properly preserved if do not use the machine for long time. The machine should clean before storing, then put the machine on a dry place.

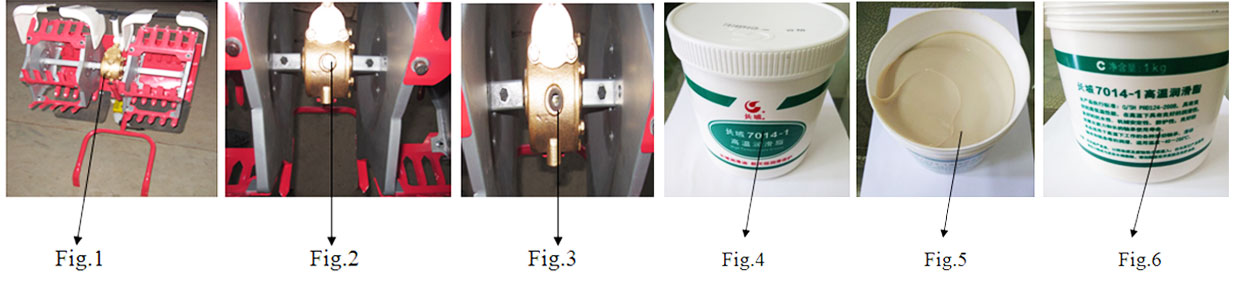

Fig.1: Filling engine oil from here(Please use the high temperature grease only)

Fig.2、3:Remove the screw and fill the high temperature grease (Filling high temperature grease by grease gun at the end of each working day)

Fig.4、5、6:Recommend to use the “GREATWALL” brand high temperature grease.

|

Common Faults |

Fault reason |

Solutions |

|

Blade axis not turn or speed too low |

Clutch slipping |

Clean the oil pollution of clutch

|

|

Worm gear damage |

Replace worm gear |

|

|

Weeding effect not good |

Blade wear or blade screw loose |

Replace blades or tighten the screw |

|

Worm gear box body temperature too high |

High temperature grease too little |

Fill or replace high temperature grease |