15HP Threshing Machine

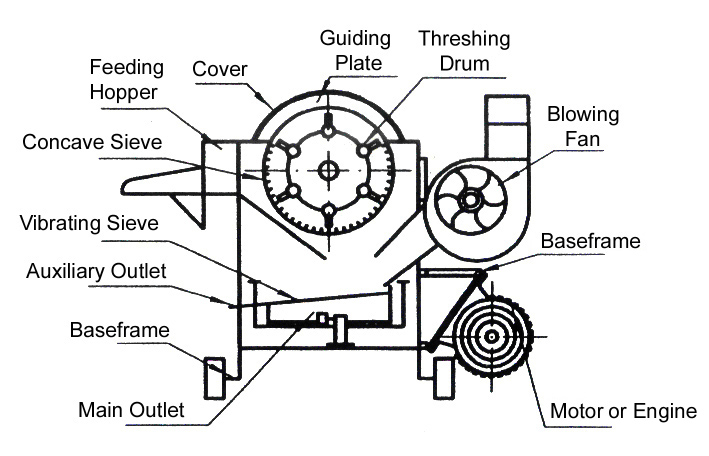

15HP 5TD-90 rice thresher is full feed paddy thresher, and is in line with the standard GB/T5982—2005 test method for threshing machine. It is mainly composed of the feeding hopper, the frame, the concave sieve, the threshing drum, the cover, the guide plate, the fans, the vibrating sieve and the transmission devices etc.The multi-function paddy thresher is widely used to thresh rice, corn, soybean, sorghum, millet, oil seed etc.

|

Specification

|

Unit

|

Parameter

|

|

Drum speed

|

r/min

|

1050

|

|

Power

|

HP

|

≥15

|

|

Vibrating sieve frequency

|

Hz

|

330

|

|

Amplitude of vibration

|

mm

|

40

|

|

Productivity

|

Kg/h

|

800-1200

|

|

Weight Without Engine

|

Kg

|

260-360

|

|

The rate of not threshing clean%

|

Index

|

≤1.0

|

|

Crushing rate%

|

Index

|

≤0.5

|

|

Unit power productivity(kg/kw.h)

|

Index

|

≥180

|

Threshing machine or thresher which is farm machine for separating rice,wheat, peas, millet, sorghum, soybeans, and other small grain and seed crops from their chaff and straw.This threshing machine is mainly composed of the feeding hopper, the frame, the concave sieve, the threshing drum, the cover, the guide plate, the fans, the vibrating sieve and the transmission devices etc.

This rice thresher takes advantage of the combination of the threshing, winnowing and screening methods. It can completely separate unhusked rice from straw, rice bran, impurities with one time. It’s designed compactly and perfectly. This threshing machine reliable in operation, easy and convenient in installation and maintenance. It has high threshing rate, low loss ratio, low energy consumption etc. Thereby, it saves manpower and material resources, shortens the harvest period. It is welcomed by the majority of users. It is widely used in the rural, hilly, plain area for the rice etc.

a: For every 40 hours of work, the drum and fan bearing should be checked and a proper amount of grease should be added.

b: At the end of each use, the thresher should run for 5 minutes without feeding to exclude the remaining material in the machine.

c: At the end of the operation, the condition of the machine and parts should be checked and the maintenance is carried out.

d: Every 8-10 hours of work, check the bolts of bearing seats, drum bolts and other important fasteners in time, to ensure the fasteners is firm and reliable.

e: After every season's operation, check the status of each component, clean up the debris in the machine, clean the bearing parts with gasoline and add grease, paint damaged area should be painted, and the machine is stored in the warehouse.

When replacing the drum parts or nail teeth, the drum must be adjusted for static balance. When replacing the fan impeller, the impeller must be corrected with the static balance.

|

Failure phenomenon |

Analysis of causes |

Troubleshooting; |

|

No straw at the straw outlet

|

1. The turning of the drum is incorrect.

2. The installation of the guide plate of the cover is reversed

3. The speed of threshing drum can not reach the required speed. |

1. Check and correct.

2. Check and correct.

3.Check whether the tightness of the v-belt is suitable or to increase the accelerator of the diesel engine

4. Check whether the motor has reached the rated speed |

|

Threshing is not clean

|

1. The speed of threshing drum can not meet the requirement

2. Serious wear and tear of nail teeth |

1. Make the drum reach the rated speed

2. Replacement of nail teeth |

|

Great loss

|

1. The amount of feeding is large and uneven.

2. Low crop yield and not full grain |

1.Reduce feeding amount and uniform feed

2. Replacement of crops |